By definition, commercial paving projects are a delicate balancing act. Cash-strapped municipalities and businesses operating on thin margins need to find materials that can withstand unpredictable weather, high traffic volume, and heavy loads. The finished product, whether it’s a parking lot, a road, or just a driveway, needs to perform and last with minimal maintenance.

While many will opt for the same commercial paving solutions they’ve always used, some are looking for alternatives. They find them with Unit Paving. Let’s compare the relative strengths and weaknesses of common commercial paving materials.

Asphalt Pavement

Asphalt seems to be everywhere. It’s the most common commercial paving material because it’s easy to manufacture and transport, and relatively quick and cheap to install. On the plus side, it’s easy to repair, resists erosion, and has a bit of give that allows it to adapt to a variety of soil and weather conditions.

It also has significant drawbacks. Because its binding material is petroleum-based, it’s a finite resource. Because of its petroleum content and the heat island effect (asphalt absorbs and traps heat), it raises local temperatures, and is also harmful to the environment. Its installation is very labor-intensive and can be dangerous. It’s impervious, so it contributes to stormwater runoff and flooding. It’s soft, leaving it prone to potholes and cracks. And its petroleum component makes recycling difficult and expensive.

Concrete Pavement

Concrete tends to be more durable than asphalt. It’s also more versatile, since it can easily be shaped, colored, and textured to look like something else. The materials that make up the aggregate are easy to grind down and recycle or repurpose, and it’s reflective to help mitigate the heat island effect; these factors make it more environmentally-friendly than asphalt. Some forms of concrete are even designed to be pervious or porous to aid with runoff control.

However, even concrete has its disadvantages. Not as flexible as asphalt, it can be prone to erosion and cracking. Like asphalt, it also requires a lot of specialized equipment to install properly, which drives costs up relative to asphalt and permeable pavers. And because most concrete surfaces aren’t designed with sustainability in mind, they will — like their asphalt counterparts — place heavy demands on local drainage systems.

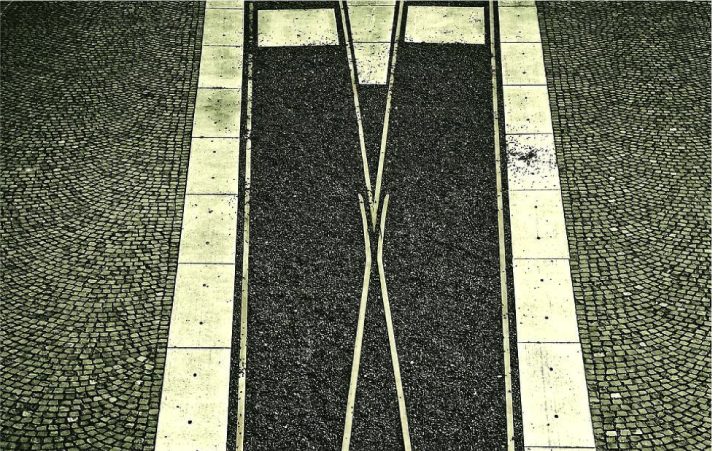

Permeable Pavers

Permeable pavers are extremely durable. On their own, they can be driven on by cars, trucks, and all manner of heavy equipment — they’re capable of handling more than 6800 PSI of ground pressure. Once filled they’re even stronger, offering more than 8000 PSI of compression strength. That’s more than adequate for any volume of commercial traffic.

They’re low-maintenance, being as easy to replace as they are to install. A smaller project can easily be handled by a single person, while a larger-scale project can be completed quickly by a smaller team than a concrete or asphalt pave would require. The fill material can be locally-sourced, and the pavers don’t require sealants. Because they absorb water rather than shedding it, they’re far more environmentally-friendly and will require far less drainage; that, in turn, cuts down on flood concerns, soil erosion, and depletion of natural resources.

For all the advantages (and they are legion), pavers do have some challenges. The amount of preparation in terms of backfilling, grading, and compacting is about the same. The cost is less than concrete, but may be slightly more than asphalt. And because they’re not as commonly used as concrete or asphalt, finding a qualified local installer can be challenging.

Challenging, but not impossible. If you require commercial paving in the Carolinas, Unit Paving Inc has the tools, expertise, and experience for commercial paving projects of all sizes. To find out how cost-effective a permeable paving solution can be for your business or municipality, contact Unit Paving to explore your options.